HOME

What's New

CPU Cooler

Programs

Introduction

AmnHLT

CpuIdle

Rain

VCool 2.0

Waterfall Pro

Current Tests

Test Archives

UDMA Driver

Tests

Windows 95

Windows 98

Windows NT

Way 2 Cool

Projects

Compaq 1800T

1800T Temp Monitor

Celeron-A

Going for 504

More on 504

Cheap Sandwich

BX6r2 Diode Fix

Condensation

Lap that Slug

Celeron PPGA

Journey to 1080

Building an NT Box

Heat Pipe 1

Heat Pipe 2

Heat Pipe 2.2

gp_Temp

gp_Temp4

gp_Temp5

Heat Sinks

Aavid

A&C Prototype Sink

Alpha P125

Alpha P521

CPU Cooler

FullWay

Tom's Sink

Water Cooler 1

Water Cooler 2

Water Cooler 3

Water Cooler 4

*

Water Cooler 6

Water Cooler 7

Way 2 Cool

Thermometer

Thermometer 2

K-6 heat sink

Case Cooling

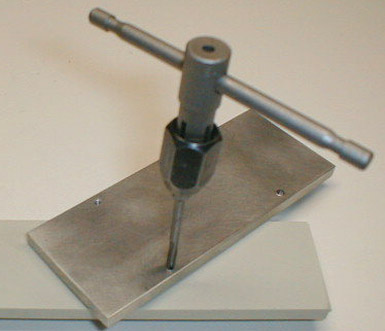

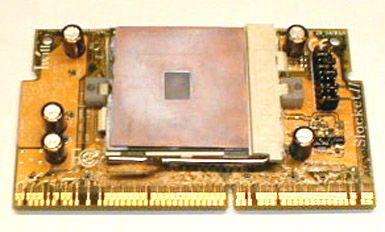

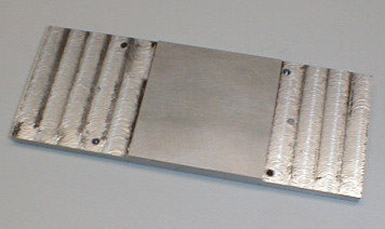

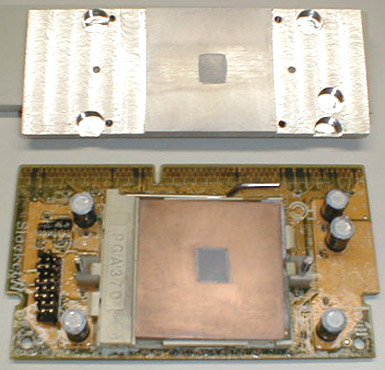

Heat Sink Tester

More Case Cooling

Klamath heat sink

Q500A Cooling

My Server Temps

Temp Calculators

CKS400 Rack Case

Fan Controller

Cooling Links

Downloads Page

Tips and Trix

Dual Boot Win95 / 98

Dual Boot Linux/NT4

D-B Linux/Win2k

Hot Flash your BIOS

Family Stuff

Prom / St. John

Providenciales

Email Jim |