|

I just had the opportunity to test what turns out to be good way to get into the 500+ zone without spending a lot of money or spending hours of designing and cutting up chunks of aluminum. Tom Leufkens has come up with a relatively inexpensive, good performing TEC-assisted heat sink. As Tom has not come up with a name for it yet, I guess I'll just refer to it as "Tom's Sink." Not too catchy, but accurate.

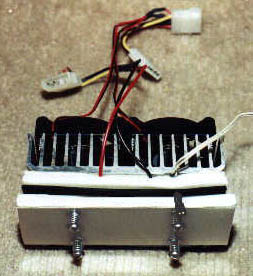

The sink arrived assembled with the following

components:

Since I have been running Peltier sinks for a while and have had some problems with condensation, my Celeron has already been sealed with a polyurethane coating and the entire SEPP is encased in closed cell styrofoam. I have replaced the Aavid heat sink I had been using as a rear plate with a piece of fiberglass with more insulation facing the back side of the SEPP. This has gotten rid of the problem of condensation forming on the rear plate from the cold migrating through the processor. With this setup, I had no need of the acrylic rear backing plate supplied in the kit.. I also opted to use my longer screws with springs over the 6-32 machine screws supplied with the sink.

Tom's sink mated to the Cele and my backing plate.

The Celeron is hidden in the insulation.

The sink has no mounting tabs to hold it to the motherboard, so I was happy my backing plate (which fits into the holders on the motherboard) was present. The sink is not so heavy as to be a problem, but some mounting tabs on the acrylic backing plate would be a nice touch. Two electrical connectors to connect and it's time to try it out.

Performance

The first thing that struck me as I started

the system up for the boot up test was how fast the TEC started cooling

the slug on the Celeron. This, as I said, was a byproduct of the

small cold plate. Within about 10 seconds the temperature of the

slug had dropped 10°F. This TEC kicked butt on the 40mm TEC I

had been using. After a small rise in temperature as Windows finally

loaded at about the 90 second mark, the temp dropped quickly as Rain kicked

in. By the end of the 4 minute test, the temperature of the slug

was just below 20°F.

After another couple of minutes, I was ready to run the Q2 test. By this time the slug temperature had dropped below 18°F and the Celeron's internal diode temperature was hovering at 26°F. Pretty cold for a single TEC on an air cooled sink.

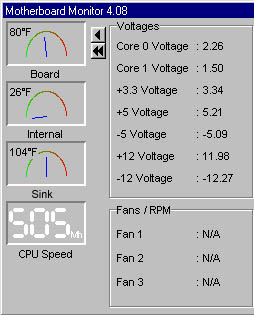

Time to start logging with Motherboard Monitor 4.08, and start the Quake2 demo test. The test consists of two runs each of the two Quake 2 demo maps and returning to Windows to watch the cool off. Notice that with a 74°F room temperature, my well ventilated InWin Q500 is showing a motherboard temp of 80°F. The air temperature inside the closed case (not shown) was 76.6°F at the time this shot was taken.

Good performance for an air cooled sink. As is common with all of the single peltier heat sinks I have played with, the peltier seems to have a tough time keeping up with the heat produced by the processor. This TEC handles it better than many and much better than the one I was currently using. With a more powerful pair of fans, both the heat sink and diode temps will come down a bit more. At $60 for the whole assembly, this is definitely one inexpensive way to push past the heat related crashes which keep many from making the jump to the 500 mark and beyond.

Though I trashed the log file by mistake, after an hour of a Q2 LAN game, the internal diode temperature peaked at 87°F with the sink temperature holding steady at 122°F. With my Celeron, an internal temperature higher than 95° can result in lock ups in Q2. Were this my only sink, I would choose the upgraded fans to insure stability.

Pros & Cons

Pro

Good bang for the buck. At US$60,

you get a TEC sink that allows even my stubborn 300A to run stabily at

504 MHz. This is something it won't do with a non TEC aided P125

Alpha.

Con

I would have liked to have seen the insulation

fit a little tighter, as any air space leaves room for condensation to

form. I also prefer closed cell styrofoam to the flexible, soft foam

that comes with the unit. In a quick test using a bare 100 watt light

bulb as a heat source, the foam from the top of an egg carton outperformed

the soft foam by a margin of about 30%. (Yeah, I know, me and my

egg cartons again.)

Errata

The temperatures that this sink will bring

the processor down to are well below the dew point. Condensation

may form. One of the places condensation occurs is beneath the slug

on the pins used to connect the chip to the Celeron's circuit board.

Moisture here will, at the very minimum, cause you to shut down abruptly.

It would be a good idea to look into ways to waterproof the SEPP.

Conformal coatings are one alternative. If you happen to be out of

that, I have used furniture grade polyurethane with excellent results.

(More on that in an upcoming article.)

Where to get it

Joe at Overclockers.Com

has the sinks for sale. He has a review of the sink and the sales

information. If you have questions or comments on the sink, email

Tom

Leufkens.