Tear it down

5-24-00

Well, it's been a little over seven months

since Water Cooler 4 was installed on my Windows box. Since it's

time for a processor upgrade and, of course, I plan to water cool and add

some peltiers to it, I though it would be a good idea to strip it down

and see what 7 months of chillin' does to a rig. During this time

the processor was run mostly at 633 MHz. Yes, it would do more.

No, it wasn't completely stable at anything above 633. If I had one

crash that I could attribute to something other than just the normal Windows

array of crashes, it would be one crash too many. As well as being

my play toy, this box keeps track of my life and I don't take kindly to

down-time.

During the seven months, I ran Rain 1.0.

Always. Now there are those that say that running a software cooler

and peltiers is a bad mix. I am not one of those people. I

tend to think that good insulation is all that is needed to get around

the condensation issues. However, the use of a software cooler does

make for some pretty good temperature swings. Consider that the normal

internal processor idle temp for this setup was about -7°F (seven below

zero) and gaming, CAD work, and a few other uses could push the temperature

into the +60°F range. That's a fairly good swing, but not really

any more than a stock heat sink would produce under some situations. (+75

to +142 for example.)

Aside from just liking the cooler programs

for their power saving aspects, another reason to run Rain was to see how well the

packaging of my cooler held up to the humidity and the perils

of condensation. I have to say that I was impressed. Not

only did the Monokote covering do its job in keeping condensation from

forming inside the peltier assisted, water cooled package, but the use

of dielectric grease completely prevented any corrosion from forming on

the PPGA processor's pins and the slotket's edge connector.

|

I can honestly say that

it was very tough to have to tear this

project apart, but before I moved on to

WC7 and even colder

temps, I needed to know more about the

long term effects of running sub-zero temperatures.

|

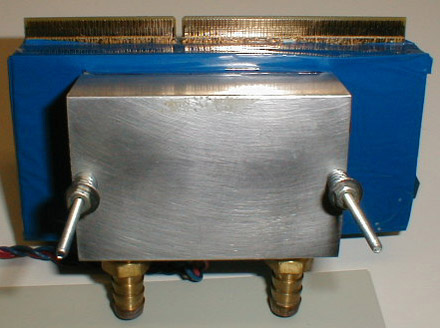

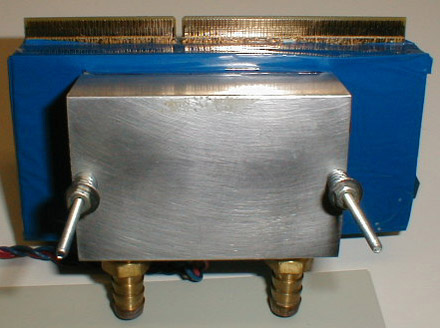

The edge connector is

clean. The dielectric grease served

its purpose well. The residue on

the face of the water cooler

block is the adhesive from the duct tape

that held the water block's thermo-sensor in place.

|

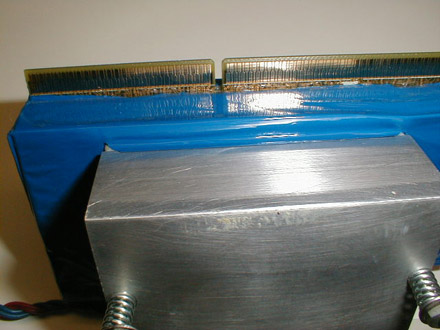

No signs of condensation

or corrosion here either. It does have a fairly nice pattern of thermal

grease though! You can see that

both the processor and adapter were coated

with polyurethane, just in case some moisture got in. The yellow

tape holds

another thermo-sensor against the edge

of the slug.

|

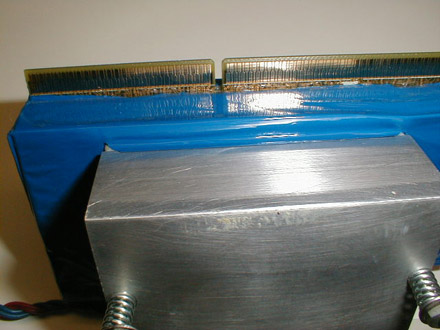

Hmmm, aside from my

strategically placed thumb print, this shot shows nothing that shouldn't

be there. No signs of corrosion.

It would appear that the dielectric grease

did its job here also.

All in all, I'm pretty happy with the way

this cooler worked out. I'd say that in this particular situation,

those who predicted that this processor would die a premature death due

to condensation were wrong. It does appear that with a little care,

running cold temps doesn't have to mean that condensation will kill your

processor. Now that the tear down has been completed, I have more

confidence that the next cooler can go a bit colder. Hopefully in

six months or so with the next tear down, I'll be able to report the same

success with WC7.