|

| HOME What's New

Workshop Stuff South Bend 405 Lathe Bench Grizzly G3103 Mill Bringing Home a Sheldon 12" Shaper

|

Sheldon 12"

Shaper - pg. 8

January 15, 2016

Attaching the shaper to the floor.

So far, I have

tried making a couple styles of adjuster feet to level this shaper

and prevent the machine from rocking/walking as the ram moves fore

and aft. Both were not as successful as I had hoped.

The first

attempt was making some adjuster feet with heavy rubber

pads. Unfortunately, these feet allowed the machine to rock when

the shaper was run at higher speeds and a long stroke. The rubber

was compressing too much under the force of the ram's movement.

This also caused the level to change.

The second

attempt was to remove the rubber pads and set the 3/8" thick steel

foot pads directly on the cement floor. This reduced the rocking,

but didn't stop the machine from creeping along the concrete as

the ram cycled.

With a couple of

failures under my belt, it was now it was time to see if I could

provide a secure mount for the shaper. I would attempt to attach

the shaper to the floor in such a way as to allow me to secure the

shaper, then level, and re-level as the shaper settles in.

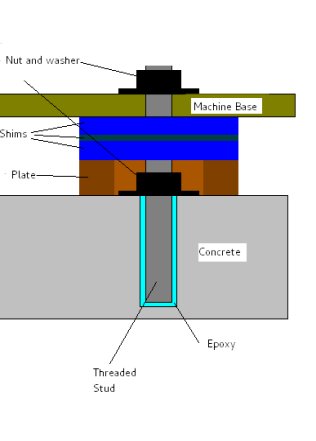

I had been reading up on the different methods of attaching machine tools to concrete and had pretty much decided on drilling holes into the concrete floor and using acrylic or epoxy to set either studs or nuts into the concrete. I had mentioned this to a friend, Dennis, who works as a plant engineer at a Newfoundland university and he helped me out with some information on the brand of adhesive he's used, A7 Redhead, and how to pre-tension the studs so that they have less chance of working loose over time. This procedure involves sinking a hole into the concrete, adding some epoxy into the hole, then installing a threaded stud. Once the adhesive has cured, a nut and washer are added to exert tension on the studs where they exit the concrete. You then add a plate with a hole large enough to encircle the nut and washer and add the shims necessary to level the machine, then use another nut and washer to attach the machine's base on top of the shims. The tightening torque for various stud sizes are included in the PDF linked above. The strength of the stud's bond with the concrete is dependent on the PSI rating of the concrete, the stud diameter, and how far you sink it into the concrete. At this point, I think I am dealing with a four inch thick concrete floor. According to the county codes when this detached garage (my shop) was built in the mid 90s, four inches of concrete laid on four inches of compacted crushed stone was the minimum thickness for a slab floor. I have no reason to think that it was poured thicker than the minimum code requirements, but will find out when I drill my first hole.

I read through the A7 Redhead PDF to familiarize myself with the product and then also read up on methods of leveling machines that were solidly attached to the floor. It would appear that using slotted shims is the standard approach and that the "best practice" was to use only three shims on any one stud. The reason for this is that there will be some air space between each shim, as well as between the plate set on the concrete and between the shim to machine base. The figures given by one manufacturer of shim kits was between 0.00025 to 0.0005" per shim. The more shims you use, the more possible air space. The more air space, the more chance the shaper will move when you tighten down the machine.Unfortunately,

the fully equipped shim kit costs more than I paid for the shaper.

Buying the shims individually would still be expensive and that

assumed that I could measure close enough to not need a lot of

extra shims. This was doubtful. Another possibility would be to

surface grind my own thicker (.25" - .50") expensive shims and buy

the less expensive thinner ones. I need the thicker shims due to

the slope of the concrete where I chose to put the shaper. The

floor has about a half inch slope between the rear right height

and the left front height. I know from experience that leveling a

machine with threaded adjusting feet is a slow process that needs

to be repeated as the machine settles in or as the seasons change.

Having to jack up each corner to insert shims would be slower

still, so I considered other ways to make the leveling

adjustments. I came up with an idea to make screw adjusters that

would surround the pre-tensioned studs. As an added bonus, this

would get rid of some of the possible air space between multiple

shims. I think this approach looks promising and I will machine

some up to see how well they work out.

|

|

| Attaching

the machine base to the concrete per the information I

have read. |

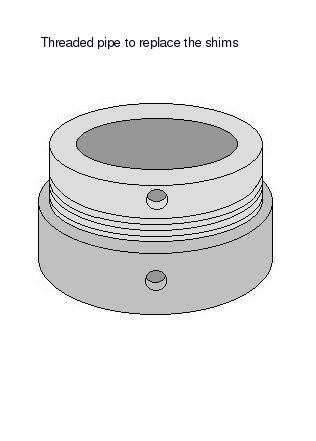

Design

for replacing the plate and shims in the previous

drawing.. |

As a proof of

concept, I made up an adjuster from 2" cast iron plumbing pipe.

Inexpensive and large enough to surround the thick washer that

will sit on the concrete.The threads are 11-1/2 TPI and tapered,

so I chucked them up in the lathe and re-cut the threads to remove

some of the taper so that I had about 1/2" of adjustment range

with good thread contact. It was a bit time consuming to pick up

the existing threads with the threading bit, but the first

adjuster turned out well enough to make the other three. I got all

eight pieces re-threaded in a couple evening's work. I then

drilled four 1/4" holes in each of the top threaded pieces to

allow me to turn the top adjuster with a pin spanner while using

an adjustable wrench on the bottom. All of the adjusters were then

put on the surface grinder to grind the top and bottom surfaces

parallel. It took a while to position each of the adjusters so

that the bores/threads were square with the grinder's table.

|

|

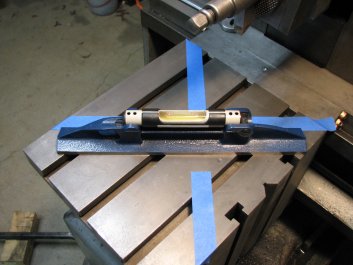

| Grinding the adjusters to be parallel on the top and bottom surfaces. | The four adjusters are done. The adjusters are shown the way the will sit on the concrete. |

All four of the

adjusters needed to be different heights. There is a difference of

about 0.5" between the tallest and shortest. With the tallest

adjuster at around 1.8", they're a little taller than I would

like, but I needed enough height to be able to fit the pin spanner

and the one inch thick adjustable wrench to make the adjustments.

I had measured the gap between each of the existing adjusters of

the leveled shaper and the floor and cut and ground the new "ring"

adjusters as close as I could get them to those measurements.

Hopefully the shaper will be close to level without having to

start the leveling process from scratch.

|

|

| The two

adjusters in the front are shown bottom side up. |

Once

each hole was drilled, it needed to be cleaned of concrete

dust. |

I lifted the

shaper with my improvised gantry and set it on pipes so that I

could roll it from side to side as I drilled the holes in the

concrete. By being able to roll it from side to side, I wouldn't

have to disconnect the wiring conduit. Once I had centered the

shaper where I wanted it, I punched marks in the concrete for my

holes. I started with a 1/4" bit in the hammer drill and drilled

down about 4". I pushed the bit a little farther and broke through

the slab at about 4.5". I followed this up with a 3/4" bit.

Now that I had confirmed that the slab was about 4" thick, the

remainder of the holes would be drilled just shy of that depth. I

made a short plug up from some 3/4" OD pipe with a wood dowel

fitted inside and sunk it into the first hole to stop the adhesive

from running out of the bottom of the hole I broke through on. The

masonry bits tend to wander a little, so once I had the two holes

on the right side drilled, I rolled the shaper over the holes and

inserted my 5/8" studs through the holes in the shaper's base,

then rechecked the punch marks on the left side. I rolled the

machine to the right and drilled the two remaining holes. After

checking that all four studs fit the machine base and the holes

without any of the studs being tilted, I was ready to clean the

holes and apply the adhesive.

|

|

| A staged photo showing the hole depth and the cleaning tools. | The ring adjusters are set outboard of each hole and the studs are test fit. |

When I had

looked for the A7 Redhead adhesive, I found that Home Depot

allegedly carried it. When I went to purchase it, I was told that

it was only carried in their larger stores. I was told that they

had something similar. Sika Anchorfix-2. The tubes didn't have

much info other than the curing time at each temperature range, so

while I was in the store, I found the Anchorfix-2

specification PDF online and compared it with the A7 specs.

Very close to the same specifications for pull out strength. I'd

give it a try.

The instructions

state that the holes need to be cleaned of any loose material. I

used a round brush and compressed air to clean the holes until I

saw no more dust when pumping the brush up and down.

I moved the

shaper back over the holes and placed my adjusters just outboard

of of their respective final positions. Each adjuster was set to

it's final estimated height plus 0.375" to compensate for the 3/8"

raised pad surrounding each hole on the shaper's base. I wanted to

make sure that the 5/8" studs would align with the 3/4" holes in

the shaper's base once the adhesive cured. There wasn't enough

room to use a square to check for the studs being perpendicular,

so I used some 3/4" OD / 5/8" ID bushings to center each stud in

the machine's base. It wouldn't be good if I couldn't lift the

machine off the studs once the adhesive set up.

With the shaper

aligned with the holes, it was time to set the studs. I removed

each stud and filled the hole a little more than 3/4 full of the

adhesive. I then threaded the stud into the adhesive until it

reached the bottom of the hole. I placed my flanged bushing

between the stud and shaper's base, then added a washer and nut. I

tightened the nuts just enough to make sure that they remained

vertical. I rechecked all of the studs a couple times to make sure

that they hadn't shifted position and left the adhesive to cure.

We've had a warm week for January (high 50s to mid 60s°F) and the

temperature of the slab was about 35°F. The curing time for the

adhesive was said to be about 3 hours with the concrete being

+32°F to +41°F. Below 32°F, the curing time is 24 hours. I'd let

it set up for 24 hours just to be on the safe side.

The next

evening, I set up to install the nuts and washer to pre-tension

the studs. Since I hadn't unhooked the wiring and conduit, this

required me to lift the shaper a couple of times to get access to

each of the studs. I made sure that each washer sat flat on the

concrete, then torqued the nuts down to 80 foot pounds. This is

the specified upper limit for a 5/8" stud in a 3/4" diameter hole

and is said to give a tension bond strength of over 3000 pounds

for a 4" hole depth. After setting the height of each adjuster per

the measurements I had taken previously, each adjuster was

installed over the stud. We'll see how close the measurements I

took of the leveled shaper turn out to be.

|

|

| Lifting the shaper so I can get the nut, washer, and adjuster on to the front right stud. | The shaper is now resting on the four ring adjusters. The next step is to level the machine. |

With the shaper

now sitting on the four adjusters, I was ready to level the

machine. I laid out some tape lines on the table to form an X with

90° angles, then cut some tape away to allow the levels to contact

the table. I would level the table in three steps. First with my

Moore and Wright 12" level that has a resolution of 0.0035"/10",

then my new to me Stiefelmayer 8" level that was a Christmas

present from my friend Dennis. Its resolution is 0.001"/10". I

like measuring tools a lot and I am quite pleased to have another

quality level. Thanks Dennis.

Last, I would

make the final adjustments with my import frame (box) level that

has a resolution of 0.0002"/10". I could have skipped using the

Stiefelmayer, but wanted to play with my new toy. I had previously

checked it against itself and my import level on the surface plate

and it's within a quarter increment of reading true. Somewhat

puzzlingly, it does not appear to have a vial adjusting screw - or

at least, I haven't found it yet. I will need to do some reading

to see how the level is calibrated.

|

|

| Using

the 12" Moore and Wright 0.0035" per 10" engineer's

level to get close. |

Opposite angle. We're within a quarter of an increment of level. |

Using the Moore and Wright, I found that one diagonal was set about as perfectly as the level can read. The other was out by one division. I guess I did a pretty good job of measuring. I reset the ring adjusters to make the correction, then reversed the level to cancel out any error and rechecked the readings. The level was centered on both diagonals.

|

|

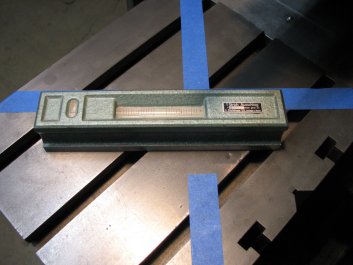

| Checking

with the

8" Stiefelmayer

|

Interestingly, this more accurate level was spot on in agreeing with the Moore and Wright. |

The Stiefelmayer

level's bubble was spot on for both diagonals even though the

resolution is three times higher. This surprised me a bit and I

reversed the level a couple times to recheck, but the bubble

centered each time.

The import level

showed two increments out on one diagonal and one out on the

other. I made the adjustments to bring it as close as I could get

it to level and installed the top nuts and washers that would hold

the machine to the floor. I now needed to tighten the nuts to

about 15% less than the 80 foot pounds of the pre-tensioned studs.

As I guessed it would, the level now changed by a couple

thousandths. I tightened the nuts incrementally in an X pattern.

Each additional 10 foot pounds I tightened one nut brought the

shaper out of level, then back into almost level when I tightened

the opposite nut. When I reached 70 foot pounds for all four nuts,

the machine was out of level in both directions by about a

thousandth. I messed around with the adjusters for another couple

hours and got it within one division in either plane with the full

70 foot pounds on all nuts. The shaper was now level to 0.0002"

per 10" for the time being. I called it quits for the night.

I highly doubt

that the shaper will stay leveled to this precision. I am pretty

sure that in the past six years that the shaper has not been

secured to the floor. The pads on the flange that the adjusters

rest against are only 3/4" thick and the rest of the flange is

only 3/8" thick. It's not what I would call that sturdy of a base.

Since the previous owner didn't have the shaper on adjustable

feet, I assume that there had been unequal pressure on the four

pads when it sat on his concrete floor. I am guessing that this

might have imparted a bit of twist to the shaper's base. Couple

that with the fact that my shop is only heated when I am in it and

the concrete's rate of expansion is different than that of the

cast iron

shaper base, I figure that it's going to move around some as it

gets settled in. How much, I don't know, but I will be interested

to find out. After re-leveling a few times as the base settles in

on the adjusters, I hope I can keep the shaper's table close to

level for those critical setups that happen every once in a while.

It took me two

days to get back out to the shop. I checked the table for being

level and it hadn't changed. I reinstalled the shaper vise and

checked the vise rails for level. It was one tenth high on the

left side. I'm pleased with that. We'll see how well the shaper

stays level once I run it for a while.

Speaking of

running the shaper, bolting it to the floor has made a big

difference in the way the shaper runs. It's more quiet and

operates more smoothly now. I didn't realize how many of the

noises that I previously heard were simply due to the shaper

rocking against the concrete floor. Of course I now wanted to put

the shaper to work and make some chips. I spent a little time

squaring up some Durabar for the next project and tried cranking

up the stroke speed. I am now able to run the shaper at full

speed. There is no more rocking or shaking and the clapper doesn't

bounce as much as it did before the shaper was secured to the

floor. This alone is worth the time spent on securing the machine.

I am finally to the point that I feel comfortable that I can use

the shaper to make some projects.

The next project

is to make a new crank handle for the shaper. The current handle

had been broken and welded back together. While it works, I'd like

one that both works and looks good. The handle uses a 1/2" square

hole to attach to the four square shafts it fits on. Cutting the

square hole is a perfect project for a rotary broach. Since I

don't own one, I will try my hand at making one. I'd like to make

one that will attach to the lathe's quick change tool post, so I

will need a tool holder that can hold a couple bearings. Making

the broach tool holder will require me to cut some dovetails. This

will be a good way to get some practice using the shaper. I am

looking forward to spending some time working with the machine.

|

| I finally have a better heat source in the shop. The water vapor and rust producing propane heater was replaced with a pellet stove. It works well. |

| Shaper 1 |

Shaper 2 |

Shaper 3 |

Shaper 4 |

Shaper 5 |

Shaper 6 |

Shaper 7 |

Shaper 8 |

Shaper

9 |

© Fager January 15, 2016