Sheldon 12"

Shaper - pg. 5

September 28 to October 14, 2015

After finishing

scraping the tool head and swivel block and reworking the lock, I

decided that I had to paint the tool head. I really hadn't planned

on stripping and painting anything on this machine at present,

aside from shooting primer on the missing front panel and the

repair I made on a side cover. However, after all of the work I

had done on the tool head, looking at the two different colors of

flaking gray paint and all of the chips on the tool head made me

decide to spruce it up a bit. Since I have started down this

slippery slope, I will also paint the other parts I have repaired

and put primer on. At this point, I don't plan to paint the whole

machine. I would rather get some time in using it. I've had it

since the end of May and only have about two hours total time of

using it.

I used some aviation stripper, then wire brushed, then sanded the

tool head, taped it off, and shot a couple coats of primer on it.

I really can't tell if the darker paint below the light gray with

a bluish tint was another coat of paint or maybe a darker primer.

I like the darker bluish gray better than the lighter color, but

many of the Sheldon's I've seen pictures of match the lighter

color. While I had considered having the original paint matched

and going with some Benjamin Moore Urethane Alkyd Industrial

Enamel as I had done with my South Bend lathe, I decided against

it and purchased some Steel Gray paint from Tractor Supply. I also

purchased some black and some blue. I would attempt to come close

to the darker color by mixing the paint myself. I've used this

paint before on one of my tractors and it holds up pretty well. It

doesn't seem to chip as easily as some of the other enamels I have

used.

After I sanded the tool head with 220 grit paper and put the

second coat of high fill primer on the tool head, I had some time

to kill before calling it a night. My next scraping job would be

to scrape the boss that the table support rides on. I also needed

to scrape the bottom of the support itself. I hadn't decided which

surface to start with at this point. To get started with this job,

I first needed to map the surfaces I would be scraping. I set up a

magnetic indicator base on the bottom of the table and ran the arm

down toward the boss. I attached the DTI and measured the boss for

being parallel with the travel of the table and cross rail ways. I

measured in three positions: The rear side of the boss, the front

side and the center. All three measurements were within a couple

tenths of agreeing with each other across the length of the boss,

but the boss seemed to be out of square in two directions. The

boss was high on the left side by 0.0025". This was over 12 inches

of the 16.5" boss. Not terrible, but not to the Sheldon spec of

0.001" in 12" and I wanted to get it closer to 0.0001" if I could.

|

|

With

the old paint stripped off of the tool head, I gave it a

couple coats of high fill primer. Once it dried for 24

hours, I again sanded with 220 paper.

|

I

measured the top of the table support boss from left to

right. The boss was low on the right by about 0.0025" over

12". The boss is 16.5" wide.

|

The next step

was to measure the front to rear surface of the 1 9/16" wide (Y

axis) boss in relation to the top surface of the table. I had

previously measured the table in relation to the stroke of the ram

and after adjusting the ram gib, had proven that the ram and table

were in the same plane within 0.0001" over the length of the 12"

table. Now I wanted to get the boss to match the ram and table as

close as I could. I set my camelback straight edge on the table

and attached the mag base for the DTI on the under side or the

straight edge. I could now slide the straight edge across the

table and read the relative height of the boss. This boss was

angled a bit more than I figured it would be. About 0.002" in 1

9/16". That's a lot.

I decided to

check the table support to see if the bottom surface was 90° to

the mounting surfaces. I was surprised that I couldn't detect any

light between the vertical leg of the square and the two surfaces

that bolt to the front of the table. The support base is square

with the mounting surfaces, but the boss it rides on is not square

with the table. I wouldn't have been surprised at less than 0.001"

over a little more than an inch and a half, but 0.002" was a lot.

I needed to give this some more thought.

I tried a pivot

test on the table support bottom surface against the surface plate

and it pivoted at the center. This showed that the surface was

slightly convex and high in the center. This is no surprise as

sliding surfaces usually pick up more swarf on the outer ends than

they do in the center, and consequently the wear is greater at the

ends of the shorter sliding surface. Because I was still unsure

what to make of the measurements I taken on the boss, I decided

that I would start scraping the table support first. The support

is pretty scarred on the bottom. There are also some wear lines

that are not parallel with the bottom rectangular surface. It

appears to me that the support had been mounted cocked on the

front of the table at some point in the shaper's past. I also

noticed that the way wiper felts on the support base were worn out

and not doing their job of keeping swarf from getting between the

support and the boss. Knowing that wiper felt replacement is often

overlooked, I had purchased enough to last me quite a while. I'd

replace these once I scraped the bottom of the support.

|

|

Using

the straight edge to support the DTI, the boss appears to

be out of parallel with the table by 0.002" across the 1

9/16" section of the boss.

|

Amazingly,

even though the bearing surface of the table support is

scarred and worn, the attaching surfaces are square with

the bottom.

|

The first print

I took of the table support base showed color in the center, but

more color on one side than the other. This didn't necessarily

mean that one side is more worn as I could have just put a little

more pressure on one side while I was marking it. When a piece is

high in the center, it will rock as you try to print it. Before I

started scraping, I mounted the inked table support to the table.

I would try to wear off the print I had just taken against the

surface of the boss to see if my print matched the front to back

slope of the boss. This should confirm or refute that the table

support base is in the same plane as the boss it rides on.

However, like anyone who has tried to bring a machine into being

square with itself has found out, there is always another issue to

contend with and sometimes they don't make a lot of sense.

The table

support base is L shaped. The lower leg of the L that sticks out

has rounded corners and the side that is flush with the upright

leg has square corners. If I mounted the support with the

leg with rounded corners facing the operator, the base over-hung

the operator side of the boss by about a 5/16". If I turned the

support the opposite direction, it over-hung the inboard side by

1/4". With the rounded corners facing the ram, I could possibly

place a shim between the table and support in order to center the

base on the boss, but I am at a loss as to why this should be

necessary. Judging by aesthetics alone, I assumed that the side

with the rounded corners was meant to face out toward the operator

so the rounded corner wouldn't catch your pant's leg. If my

reasoning is correct, then there's a rather large misalignment of

the table support to the boss. As I said, it doesn't make a lot of

sense.

It has been said

that scraping is easy, but knowing what to scrape takes a lot of

detective work. The same seems to hold true for figuring out what

the machine designer had in mind.

I am trying to

play detective and am coming up with no good explanation for what

I am observing. On the somewhat plus side, the fact that the

support base overhangs the boss and leaves one side of the boss

with no contact could account for more wear on the rear of the

boss than the front, if the L shaped portion was usually mounted

facing the ram. I admit that it's only a guess, but it makes a

little more sense than anything else I can come up with.

I needed to

scrape the support base no matter what the cause of the

misalignment, so I thought I'd start with this surface and think

about the alignment of the support base to the boss a bit more.

Being only a

novice scraper, I have been doing some more reading and watching

some videos about scraping with the Biax in order to improve my

technique. After reading about how your should keep the distance

between each scrape mark about the same as the width of the scrape

mark, I realized I hadn't been doing this as much as I could. I

decided to try to slow down the speed and increase the length of

the stroke to see if I could rough scrape a little more accurately

than I had in the past. I used #2 speed on my Biax 7ELM with about

a 1/2" stroke. With the scraper angled at 45° to the long side of

the support, I moved the Biax over the length of the surface. I

ended up with scrape marks separated by spaces that were about the

same width of the scrapes. This was an improvement over my my

previous technique. It took a couple passes to scrape the color

from the first print. With each new print, I again reversed

direction and ended up with a bunch of X marks on the surface.

Slowly, I gained more bearing points. However, I found that with

the stroke speed slowed down, I needed to hold the Biax handle

tighter against my body to counteract the push of each slower

stroke. If I didn't support the Biax tightly enough, it jumped

around quite a bit.

|

|

To have

an additional way to check the table support boss being

square with the table, I decided to scrape this surface

first.

|

A few

cycles with the Biax and some cuts with a hand scraper to

break up bigger points, I began to get some color across

the bottom surface.

|

After a few

more cycles of scraping with the Biax, I switched to a hand

scraper to start working on the finish passes. I know that it is

possible to finish scrape with the Biax, but I do a better job

with a hand scraper. Once I was pretty close to the bearing I

wanted, about 25 points per inch, it was time to relieve the

center 40% by a small amount. Even though there are way wipers on

the table support, in my short time of using the shaper I found

that a fair amount of swarf lands on the boss that the support

slides against. The swarf will get under the wipers and wear the

outer ends of the support first. Hopefully by relieving the center

portion of the support base, the table support will stay flat for

a longer period of time. Relieving the center section involves

some guess work since you cannot reliably print the area you are

relieving without a specially made template. To relieve the center

40%, I cut in a cross-hatch pattern, 45° one direction, then

switched directions for the next set of passes, with each scrape

going the full width of the surface. I scraped four cycles in each

direction without printing, while offsetting my scrapes by about a

quarter inch each cycle. I tried to use the same pressure for each

scrape. If I have done this correctly, when the ends of the table

support finally wear down so that the center 40% starts bearing on

the boss, I would like the center surface to have a nice array of

bearing points. I don't know if I will achieve this, but that is

my goal.

In the picture

below right, I have the first few passes of relieving done. As you

can see by the stray bearing points in the center section, I still

have to go a bit deeper. I am now beginning to finish scrape the

center section by using shorter strokes and just cutting down the

high points as marked by my camelback placed perpendicular to the

base. Printing this way is not that accurate, but it's better than

scraping blind. I am using a good deal of pressure on each stroke

to increase the depth of the relieved area. Once I get the

relieved area finished, I also need to start splitting some of the

points on the outer ends to get a little more even bearing.

|

|

A few

cycles with a hand scraper and I am starting to get some

pretty good bearing. The next step will be to relieve the

center 40% of the surface.

|

The

base is 7.0" wide, so I relieved the center 2.8" (40%). I

still need to scrape a bit deeper as evidenced by the

stray spots in the center.

|

Toward the end

of the evening, I decided to recheck the measurements I had taken

on the boss in the Y (front to rear) axis with a level. I had seen

a little too much discrepancy in the DTI measurements I had taken

when I had tried to move the straight edge fore and aft on the

table. I rechecked the table for being level and found that it was

off by a half thousandth over the 10" wide table. While the shaper

not being level, wouldn't affect my DTI measurements of the boss,

getting the shaper level to gravity would allow me to use my box

level to confirm the measurements I had taken with the DTI.

Because the shaper didn't stay leveled over a couple week's time

probably meant that the thick rubber padded I had added to the

leveling adjusters were too flexible. While in the process of

readjusting the table level, I noticed that I could move the

level's bubble by stepping on the flange that the adjusters bolt

to. I guess this confirms that the rubber pads were allowing the

machine to move around a lot more than I wanted. I needed to fix

this before I went any further.

|

|

The

rubber pads have been removed from the shop made height

adjusters. I'm now thinking that I should have wider

adjuster feet and secure them to the cement floor.

|

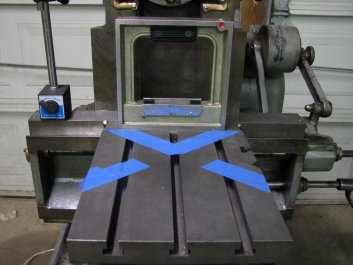

It is

easier for me to level a machine by leveling diagonally.

Having the level aligned with the adjusters makes it

easier still. The tape marks allow me to repeat my level

placement.

|

I raised the shaper and

removed the adjusters. I removed the rubber pads and reinstalled

the adjusters. Although the 2" X 3" 3/8" thick steel pads on the

adjusters are about the same size as the commercial adjusters I

purchased for a much heavier machine, I am wondering if a larger

pad would be better on the shaper. The force of the moving ram is

unlike any other machine tool I own. A wider steel pad attached to

the cement floor would probably be an improvement. However, the

new adjusters will have to wait. I needed to take some

measurements, so I now I needed to level the shaper again. As I

have said before, I like to level diagonally. The problem I

encountered with the shaper is that the leveling pads are inboard

from the corners of the rectaganal body of the shaper's base and

can't be seen while I am trying to position the level on the

table. I have found that it is easier to have the level line up

with a imaginary diagonal line between the adjusters. To help me

position the level, I measured the layout of the adjusters. 27"

wide and 22" deep. Since the table is 10" wide and 12" long, I did

some quick math. 22/27 = X/10, X = 8.148" or about 8 5/32". So I

needed my diagonal tape strips to intersect the corners of the 10"

wide table and then intersect at 8 5/32" along the Y axis. With

the tape strips now corresponding to the adjuster locations, it

was somewhat easier to level the shaper.

|

|

Table

support sitting on the boss in the direction that I would

think to be correct except that the front of the support

base overhangs the boss

|

If I

reverse the support, it overhangs the rear of the boss,

but not by as much. While I can correct for this, it

doesn't seem right.

|

With the shaper leveled again, I could now check

the table support boss with the level as well as with an

indicator. This would make it easier to bring the boss into

level with the table. I mounted the table support again to

measure how far out of alignment it was. Facing the direction

that I assumed it was meant to mount, it overhung the front of

the boss by about 5/16". If I reversed the support, it overhung

the rear of the boss by about 1/4". Since I wanted to use the

table support as a final check while scraping the boss, I

decided to machine up a shim to center the support on the boss.

I had no quarter inch flat stock, so I machined the shim from

3/16" and added a couple 1/16" washers until I could purchase

the correct stock. As shown in the picture below left, the shim

and washers centered the support on the boss. I am still at a

loss to explain why the table support doesn't align properly. I

did some looking online and found a few images of Sheldon

shapers with the table support overhanging the front boss.

Apparently mine is not unusual in this respect. I still don't

care for the setup. I think that the more surface the support

base has in contact with the boss, the more evenly it will wear.

I also think my plan of turning the support with the leg to the

inside and using a shim will work fine. It should help keep the

newly scraped surfaces from wearing unevenly.

|

|

I

made a shim from some stock I had on hand and added a

1/16" thick washer behind each leg to get the support

centered on the boss. .

|

I

found a picture online showing another Sheldon shaper

with the table support overhanging the boss. Apparently

this issue wasn't limited to mine.

|

To

scrape the boss, I would need to correct for it being angled

in two directions. The high point, viewed from the front of

the machine, is the front left corner. I used my camelback

straight edge to mark the boss. It showed color only in the

center of the boss. I forgot to take a picture of this, so the

first shot is after a couple passes with the Biax. I am using

a lot more downward pressure as I come to the left front of

the boss. I have a couple thousandths to scrape from the left

front end. I scraped until I had a few spots of color

over the whole boss, then started step scraping to lower the

left side of the boss. I also used a little more pressure on the

front side of the boss to start getting rid of the angle in the

Y axis. In a couple hours, I had brought the surface to within a

thousandth high on the left (X axis) and within a couple tenths

front to back (Y axis). Since I have been scraping with more

pressure on the left side of the boss, the difference between

the peaks and the valleys is as much as 0.0004". This makes it a

little tough to measure the slope of the boss as the indicator

bounces as I crank the table and attached indicator across its

length. I decided to spend a little time refining the surface so

I could get some better accuracy in my measurements. This might

be considered wasted work as I still have a slight angle to the

boss, but I felt that I need to get a more accurate idea of how

much to scrape to get the boss parallel with the table's travel.

|

|

Since

I forgot to take a picture before I started scraping,

here's a shot after a few cycles with the Biax and a

couple cycles with a hand scraper.

|

The

boss is still about 0.001" high on the left. I will now

scrape enough cycles to get the surface smooth enough to

map out the slope accurately.

|

After another few cycles of hand scraping, I

had lessened the height between the points and the valleys and

had increased the point count a bit more. I again measured the

slope of the boss in both directions. I was now measuring a

slope of 0.001" over the full 16.5" of the boss with it high

on the left side. Over the 1 9/16" width, I was pretty close

to level. It was time to do one more step scrape of the boss.

I decided to set up the camera and take pictures of the

process of applying color to act as a guide. I rolled marking

fluid on the left side covering about 1/5 of the surface, then

scraped it off with the Biax. Then marked 2/5 and scraped

that. I repeated this until I had marked and scraped the whole

surface. When scraping for bearing points, I would try to

leave spaces between the scrape marks, but the object of step

scraping is to evenly lower one end of the surface, so I kept

the scrape marks close to each other. I also normally reverse

directions on each cycle, but I am more consistent scraping

from right to left and with moderate pressure can scrape

0.0002" per pass. Since I needed to lower the left side by one

thousandth, five passes should get the boss close to level. I

put together an animated gif showing the process. I did forget

to take a picture of the fourth scraping pass, but otherwise,

it shows the process pretty well. I also added two shots of

measuring the surface. The indicator shows about a

ten-thousandth of slope in 16", but it really isn't quite that

close. I went from a very good points count to a very sparse

points count and there are sections of the boss where there

are two or more tenths height difference within a quarter

inch. I will do a bit of hand scraping to get an idea of where

my high and low areas are, then rough and finish scrape from

there. At least I now have a boss that is in the same plane as

the movement of the table.

|

|

Step

scraping the table support boss to remove one

thousandth inch of slope over 16.5". Click image for

animated gif (2.5 megabyte file size).

|

After

the step scraping passes, I went from a decent points

count to next to no points at all, but the boss is now

pretty much level with the table.

|

As usual, making a print of the newly step

scraped surface is a bit of a let down. It now didn't have

much in the way of bearing points. I made a couple passes

just picking the tops off of the few points I did have until

I could get an idea of the high and low areas. I then made a

couple passes at 45° with each scrape covering the entire

width of the boss. I refined the surface a bit more and

decided that it was time to put the level on the boss. I

knew I was close to level, but was pleased to see that the

level's bubble was aligned with the center

indications. Less than a ten-thousandth out over ten inches.

Not too bad at all.

|

|

After

one pass with the hand scraper, I am beginning to

see where my high and low areas are located. I have

some more scraping to do.

|

Double

checking the plane of the support boss against the

plane of the table on a leveled shaper. I couldn't

have asked for a better reading.

|

Checking the boss over the short side was

a bit trickier. With less than two inches to rest the

level on, the measurement wasn't going to be as accurate

as measuring on the longer axis, but I was just looking

for confirmation that the measurement I had taken with the

DTI was close to what the level showed me. Again, the

bubble lined up with the center marks on the vial. Now all

I needed to do was to print the boss again and start

refining the surface.

|

|

With

the level set across the 1 9/16" boss, some

inaccuracy is expected, but the level shows that

this plane is pretty close to level with the

table.

|

Another

couple of cycles with the hand scraper and I am

beginning to see some color across the whole

surface. Finish scraping is the next step.

|

Refining the surface from the

cross-hatch rough scraping I had done went pretty

quickly. I started by scraping off as many high points

as I could get with half inch strokes using the hand

scraper. I kept scraping at a 45°angle and reversed

directions of the angle on each cycle. I continued this

for a few cycles, then switched to scraping off

individual spots. If I had a group of spots angled to

the left, I scraped through them to the right and vise

versa. It took about five more cycles to get to the

picture on the lower left. The boss now had areas of 35

or more points per square inch in some areas and as few

as 25 per inch in others. While I would like to see the

points count to be a little more consistent, my number

of points per square inch is in excess to what's

necessary for this surface. Even though I have been

scraping for almost a decade, I still have much to learn

about getting a consistent pattern and points count on

what I scrape. However, I have gotten a lot quicker at

refining surfaces since I started work on this shaper.

To be able to take a surface from less than one point

per square inch to 25+ in an hour or so is pretty quick

for me.

|

|

I am pretty close to done scraping the

boss. I have a few sparse areas and will scrape

another pass or two, but am pleased with my

progress.

|

Taking a test cut. With one side of the

CI block surface ground, I planed the other

side. The planed surface came out pretty close

to parallel.

|

With all of the scraping done, I

finished up painting the tool head, table support, and

the vise parts. My paint mixture is a little darker

than the paint on the rest of the shaper and looks a

little more blue when not in direct light. In the

picture above right. the tool head is the same color

as the table support, but they look very different in

the picture. Enough about the paint. Time to take a

test cut.

Since the vise still needed to have the rails cut, I

needed to find an alternate means of mounting the 4" X

6" block of cast iron. I would have preferred to mount

it directly to the table, but didn't want to use hold

downs that would need to be removed as I planed the

whole upper surface. I ended up using a two piece

milling vise. It was too tall, so I needed to put

parallels below the cast iron block I was cutting. Not

really the best way to check the accuracy of the cut,

but it would let me test whether the tool head ways

worked better and whether the lock was now working as

designed. I set the ram travel for 7" and set the ram

position to have 1/2" over-run on either side of the

6" block.

I started my cut with the table moving left to right

and got used to the rhythm of the clapper box lifting

at the end of each cut and snapping closed just before

each cut began. About half way through the 4" feed in

the X plane, the sound of the clapper got a bit louder

and the timing of the noise changed. At first I didn't

understand the change in sound and rhythm, but soon

discovered that the ram stroke was lengthening and was

now up to 8". The force of the clapper closing on the

longer stroke made it sound a bit louder. By the end

of the cut, the ram stroke had increased to 10". What

the heck? Something wasn't right. However on the plus

side, I had zeroed the tool head dial and locked the

tool head before I began the cut and when the cut was

done, the tool head had not moved. I wound the table

back to the starting position and set the tool head

for another cut. 0.002" this time instead of 0.005" as

for the first cut. I reset the ram travel to 7" and

began the cut. This time, the ram stroke started

increasing at about 1/4 the way through the 4" cut.

Rather than stop the machine and reset the ram, I just

let it cut so I could check the test block for the top

surface being parallel with the bottom surface. The

stroke had increased to 11" by the end of the cut.

With the top surface of the block planed, I removed

it, put it on the surface plate, and measured it. Even

with the less than accurate two piece vise, the plane

of the top surface was within a half thousandth of the

ground bottom surface across the worst diagonal

measurement. The other diagonal was within a couple

ten-thousandths. It appears that scraping the tool

head, swivel block and gib has helped. The tool head

lock also seems to be working as designed now. I only

have to lightly snug the lock screw to keep the tool

head from creeping down and making the tool bit cut

deeper into the work. So I seem to have succeeded in

fixing the problem that I set out to repair, but have

discovered another issue that needs some attention.

Such is the way it seems to go with old iron. On one

hand, I'm happy that I have been able to take care of

something that needed attention, but I am now playing

detective again to see if I can deduce why the ram

stroke is increasing.

Next installment: trying to figure out the increasing

ram stroke.