Sheldon 12"

Shaper - pg. 4

August 18, through September 27, 2015

At this stage in

trying to get the Sheldon shaper to cut square and true, the

shaper's vise was waiting for me to plane it on the shaper.

However, before this could be done. I needed to take care of some

of the issues I had noted when I was cleaning up the shaper.

Since I had the tool head

and the adjoining swivel block removed from the ram, I decided to

see if I could figure out why the tool head gib adjuster was

standing proud of its alignment hole. In the second installment, I had

noticed that the screw that held the tapered gib of the tool head

slide stuck out from the gibbed way enough that the collar of the

adjusting screw wasn't seating fully in its hole. This didn't seem

right, especially considering that this machine obviously had some

wear. All else being equal, the more wear on the tool head

dovetail ways, the deeper the tapered gib should seat. I was

also having trouble locking the tool head from moving during cuts.

I had already had the tool head apart once when I cleaned it, but,

at that time, I didn't do any measuring or put the parts on the

surface plate to check their flatness.

This time, I would inspect the tool head a little more thoroughly.

I again pulled off the crank handle, removed the Acme screw, and

took the tool head slide off of the swivel block. I then put the

tool slide bottom ways on the inked surface plate. When I checked

for color, I had only three contact points. One point on each end

of one way and a very thin stripe of color on the outer edge of

the other way. The thin stripe of color on the edge of the way was

puzzling. The edge of the sliding way had a raised burr where the

flat way met the side of the tool head and it had dug a

corresponding groove in the swivel block surface. I have no

clue what could have raised this small jagged edge. The front

surface of the swivel block that the sliding tool head attaches to

has no defined flat ways. There's just two semi-circular flat

areas and some of that is used to support the tool head bottom

ways. I used a fine toothed, single-cut file to get rid of the

ridge on the edge of the tool head way and took another print. Now

I had two spots on both ways. Each spot was at the ends of the way

surfaces. It seems that the tool head ways were a little concave.

Generally when rebuilding a sliding fit, the longer surface is

scraped flat and the shorter surface is scraped with a slight

depression of a thousandth or two covering the center 40% of the

ways. As the shorter surface wears, which usually happens on the

ends of the ways first, the depression eventually comes into

contact with the mating ways. Without the slight depression, the

ends of the ways would wear and the shorter member would rock on

the mating ways. In this case, it was the longer member that was

slightly concave when it should have been flat.

In the couple hours total that I have run this shaper, I have

noticed that the tool head and the attached cutting tool tend to

creep down while cutting. This isn't a good thing at all as you

end up cutting deeper and deeper into the work. There is a lock on

the tool slide that one would expect to stop this from happening,

but it didn't. Also, the tool head gib screw seems to sit too

high. On the rest of the gib adjusting screws, the cylindrical

collar on the screw fits into a cylindrical pocket. On this one,

the screw collar stands above the pocket by about 1/10".

When I try to adjust the gib, the screw is pushed away from the

gib toward the center of the swivel block. This makes it difficult

to get a proper adjustment between the tool head and swivel block

ways. To get the tool head to lock, I tried cranking down the lock

screw pretty firmly, but to no avail. I finally stopped the creep

by tightening the tool slide gib almost to the point of not being

able to move the slide and placing a piece of copper sheet between

the lock screw and the tool slide to increase the friction as I

cranked the lock snug. Something wasn't right.

|

|

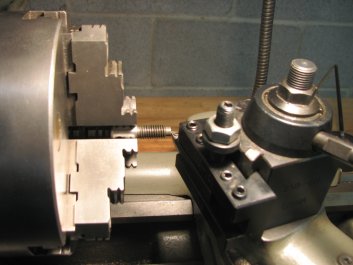

This

photo shows how the gib adjusting screw was when I

received the shaper. The cylindrical collar on the screw

did not seat into its hole.

|

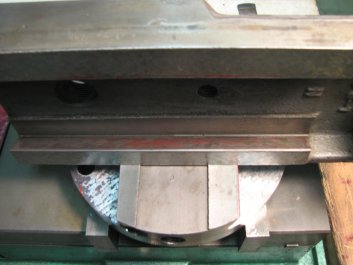

This

is how the screw should fit into its supporting hole.

The hole is drilled deep enough for the screw to go

deeper if needed to adjust the gib.

|

In the reading I did before I powered up the shaper, I'd

read that you should adjust the tool head so that you are raising

the slide when you lock it. This removes the backlash that you

would have if you locked the slide while moving the bit toward the

work. I used this method from my very first cut without it helping

the situation at all. I will give the lock situation some more

thought and revisit it after I scrape the ways.

|

|

The

tool head slide bottom ways are showing very little

contact when printed on a surface plate. The non-sliding

side of the gib also shows next to no contact and is a

bit bowed.

|

I've

marked and scraped a few passes. I'm starting to see

some color, but don't want to scrape too deep yet due to

the fixed position of the Acme screw.

|

As I thought about the tool slide operation, I realized that both

the crank end of the Acme screw and the end that threads into the

swivel block were fixed in their position. Unlike the cross slide

of my South Bend lathe, there was no movable nut to keep the screw

parallel with the ways as they wear. As the tool head ways wear,

the bushing on the tool slide that supports the Acme screw, drops

in relation to the threaded hole in the swivel block. Since the

swivel block ways also wear, this increases the angle of the screw

in relation to the plane of the ways. Since I am scraping these

surfaces, the more I scrape, the less parallel the screw will be

to the ways. Once I get the flat ways scraped on both the tool

head and swivel block, I will reassemble the pieces and check to

see how the Acme screw aligns.

After a few passes with a hand scraper, I was

getting some color on the tool head bottom ways. Both of the

inboard edges of the ways were low. I scraped a few more passes

and one of the ways now had pretty good bearing, but the other

still had no color along the inside edge. I figured that I had

scraped about two thousandths deep and had a thousandth or three

to go to get the bottoms of the dovetails flat with full scraped

coverage. However, in consideration of the screw alignment, I

think I will just refine the surface a bit and scrape the swivel

block ways. I will then put it back together and see how

parallel the Acme screw is. If I can scrape deeper to get more

bearing on the bottom tool head ways, I will.

|

|

This

is the tool slide lock. The center of the lock screw has

been polished a bit. It does not do a good job of

locking the slide.

|

The

shiny stripe on the side of the tool slide shows that

the lock has been slipping or the slide has been

operated without releasing the lock.

|

The picture above left is the tool head lock.

The circle in the center of the flat area is the end of the

screw that pushes on the outside of the tool head to attempt to

lock the slide. The cylinder to the right side fits into a hole

in the swivel block and is secured by a bolt from under the

swivel block. The bolt is sunk into a circular pocket that

doesn't leave enough clearance for the thinnest wall 1/2" socket

I own. I'm not sure why it's designed so that it is possible to

rotate the lock if the bolt loosens. I would think if you were

trying to lock a sliding member, you'd make the lock so it

couldn't be rotated. Not being able to get a wrench or socket on

to the securing bolt doesn't help much either. Since the body of

the lock was loose and has been able to rotate, the face of the

locking screw is now somewhat dome shaped from wear. It is also

has a polished finish from sliding against the outside

surface of the tool slide. The picture above on the right shows

a shiny stripe where it appears that the lock has been slipping

against the surface of the tool slide.

The more I think about the tool head lock, the more I question

the wisdom of the design. With the lock designed to put pressure

on the outside of the gibbed side of the tool head when

tightened, it applies pressure to the gib against the swivel

block dovetail way. So far, so good. However, by applying

pressure to the outside of the tool head, it moves the opposite

side of the tool head angled way away from the swivel block

angled way. In other words, it locks the gibbed side and loosens

the opposite side. This doesn't seem like a very rigid way to

lock the tool head.

|

|

Rough

scraping the bottom ways of the tool head.

|

A few

cycles later. Both inner edges are slow to get color and

I am concerned about scraping too much material off.

|

I am a bit torn between my wanting to keep the shaper stock and

wanting it to be a tool that I am confident in using. It would be

easy enough to drill and tap for a locking screw that put pressure

on the tool head gib, but I don't want to modify the machine until

there is no other choice. I admit that the more I learn about old

machine tools, the more I want to preserve the ones I own in their

original state as much as possible. However, I also want to

use the machine. That's why I bought it. If I am unable to control

the depth of cut, it's going to be very difficult to use. Once I

get the tool head and swivel block scraped, I will find some way

to keep the lock from rotating and I will put a new surface on the

tip of the locking screw and plane some metal. If the lock still

doesn't work, I will consider my options.

With the bottom ways of the tool head slide rough scraped, but not

finished, I moved on to the tool head's swivel block. I will

scrape the surfaces that mate with the ways on the slide so that I

can measure for how parallel the Acme screw is with the ways. When

I inspected the dovetails on the sliding member and the swivel

base, I noticed that there were no grooves cut at the vertex of

the dovetail ways. Instead, there is a small fillet. This is the

first machine tool I have scraped without slots at where the angle

way meets the flat way. Connelly has a chapter in his book

"Machine Tool Reconditioning" about dealing with the lack of

grooves and I re-read it. I decided that I would add a small

groove at the vertex of the angled ways so that I could more

easily scrape into the tight angle. I added the slot with the edge

of a 1/16" carbide scraper blade by pulling it along the vertex. I

dug out about 1/16" deeper than the tip of the angle. This

is just enough to allow my hand scraper blade to get into the

corner and scrape both converging surfaces flat. I'll use the hand

scraper for the getting into the corner and the Biax for for the

rest of the surface.

|

|

The

left dovetail has had a groove added to the vertex of

the angle.

|

Making

a print of the swivel block flat ways using a camelback

casting that I previously scraped.

|

Before I started scraping the swivel block, I set it on some

parallels on the surface plate and measured the top surface. The under side of the swivel block is shaped

like a top hat. The bearing surface that mates with a circular

area on the end of the ram would be the brim and the cylinder that

fits into a 3" hole is the extended cylinder above the brim. The

picture above left shows a little of the cylinder that fits into

the hole on the end of the ram. I was surprised to find that the

face that the tool head mates to was not parallel with the

circular ways on the face of the swivel block. One side of the

semi-circular surface was angled by about 0.003" over the 6.5

inches to the left. The other side way angled about 0.0015" to the

right. I was going to need to lower the top surface of the swivel

block by at least three thousandths to get it parallel with the

underside bearing surface.

Marking the swivel block was done with my 24" granite knife edge

angle template and a 18" cast iron camelback straight edge.

While I prefer marking with granite, I am alternating between the

two. If consecutive prints don't match, I've picked up some swarf

that I didn't catch when I cleaned the swivel block or straight

edge. In the staged picture below left, I show the straight

edge close to the work. In actuality, the only time it's this

close to the work is when I am marking. The rest of the time, it

sits on the other end of the eight foot bench covered with some

closed foam insulation board to keep dust and swarf off of the

marking fluid. I also noticed that there are some metal flecks on

the vise in that picture. Normally the shop vacuum has already

been used to clean up and the area is dusted with compressed air

from my compressor and air chuck. Keeping things clean helps

prevent swarf from getting between the straight edge and work and

making you wonder where all of your bearing spots have gone.

I am scraping most of the top surface of the swivel block with the

Biax. The only areas I am hand scraping are the tip of the

dovetail next to the groove, around the holes and the edges of the

circle. Trying to get into this tight a corner with so small of a

run-off groove with the Biax would result in the blade hitting the

bottom of the groove. I'd rather scrape to within an eighth inch

or so and follow up with the hand scraper. In the picture below

right, you can see a faint line that marks where the ways of the

tool head rub on the swivel block. This area was only worn a

little under thousandth deeper than the rest of the surface, but

there is a fairly deep scratch on the side with two holes that was

caused by the raised edge on the outer tool head way. Aside from

aesthetics, the scratch won't affect anything since it's below the

bearing surface.

|

|

These

are the tools for holding and marking the swivel block.

I keep the straight edge away from the scraping and

covered with a piece of foam.

|

The

section of the swivel block where the tool head ways

mate was about 0.001" lower than the rest of the

surface.

|

When working on flat ways in the same plane, such as the bottom

ways on the tool head, I would normally scrape both surfaces at

the same time. I'd print both surfaces and scrape both surfaces. I

find this helps me to keep the amount of metal I am removing about

even. However, since I had two planes angled in opposite

directions, I chose to work on the side that needed the most metal

removed first. I step scraped the side with the two holes until I

had the surface parallel with the lower bearing surface to within

a half thousandth. I then switched to the other semi-circle and

rough scraped that side until I had about the same height when

measured on the surface plate. I then began printing and scraping

both sides before printing again. About every third cycle, I put

the swivel block back on the surface plate to check that both

halves of the block were the same height as I brought in the

bearing points.

|

|

I am

starting to get some pretty good coverage with the

bearing points. Both semi-circles are now in the same

plane within a tenth or two.

|

The

bearing points on the opposite side of the swivel block.

I still need to scrape the angled way on this side. The

other side gets the gib.

|

As I mentioned before, the member with the

shorter ways is often scraped a bit hollow in the center to keep

it from rocking as it wears. However, since I was having trouble

with locking the tool head, I decided that the more contact area

I had, the better chance I had at getting the lock to work. I

ended up scraping both semi-circular areas flat. rather than

relieving the center 40% of the ways. With the swivel block

surfaces scraped, I assembled the tool head and checked the fit

of the Acme screw. It seems to be OK. It's a little difficult to

measure the angle of the screw as it is hidden between the two

parts, but it turns smoothly with no binding when the tool head

bushing and swivel block threads are at their closest points.

Since the screw turned well, I decided to scrape the tool head

flat ways to better bearing. After scraping them, there is still

a bit of a low area on the inside edges of the tool head flat

ways, but I have a lot better coverage than I had before and

don't want to remove any more metal from these ways. Once I reached the the

bearing shown in the picture below left, I made a few more

passes to split some of the larger points and called it

done. The last few passes also brought in a little more

bearing at the ends of the ways.

|

|

I

have now scraped out most of the low areas along the

inner edges. I still need to get a little better bearing

at the ends.

|

This

is the non-sliding side of the tapered gib. It may have

been replaced at some point. The spot to the left of the

cut-out is very high.

|

I checked both sides of the tapered gib for

bearing and flatness. There was a slight curve to the gib that I

needed to fix before I could get a true print. I was able to

slip an 0.002" feeler gauge under the center of the gib on the

surface plate. I took the gib to the hydraulic press and

supported the gib between a couple parallels with an dial test

indicator to measure how far the gib bent when I applied force.

It took a couple tries to get the curve out. Once I had a

relatively flat gib, I printed and scraped both sides. I checked

my progress by measuring for parallel between the two angled

ways as shown a couple pictures down. Scraping the gib went

pretty quickly as I wasn't looking for a high points per inch

count.

|

|

The

back side of the gib has been scraped.

|

This

is the initial print of the sliding side of the gib

after being straightened on the press.

|

The

next step was to measure the angled ways to get some

references before I started scraping them. I needed to know if

the angled ways were parallel with the flat ways I had

scraped. I was also curious if the machined flats on the sides

of the tool head could be used as a reference. After finding

surfaces that I would have assumed to have been machined at

the same time as the ram dovetails were not aligned, I didn't

hold much hope, but I was pleasantly surprised. The angled way

was within a half thousandth of lining up with the angled

dovetail and on the other side was about one thousandth from

aligning. The two outside flats were within a half-thousandth

of being parallel. I also added a couple precision shafts

along the angled ways and checked to see that the shafts were

parallel. They were parallel within a half thousandth over the

length of the angled ways.

|

|

The

sliding side of the gib has been scraped. Now it's time to

re-measure the dovetails so that I can keep the angled

surfaces parallel as I scrape.

|

Measuring

the angled ways with reference to the flat ways and the

machined flats on the outside of the tool head.

|

The next check was to see

if the distance between the swivel block angled ways was constant.

To check this, I needed to add the gib and measure, again using

the shafts which would contact the ways around their mid-point.

Half inch diameter shafts were just about the perfect size. I used

a surface gauge with the pins extended to contact one shaft and

the dial test indicator's stylus on the second shaft. Total error

over the six and a half inches was a little under a thousandth.

After some more measuring, I found that most of the error was

caused by the gib's sliding surface side. I scraped the gib to

correct the misalignment.

|

|

Measuring

to check whether the angled way and the surface of the gib

are parallel. They diverged from each other by less than

0.001"

|

Scraping

the angled way on the swivel block. I will use this

surface along with a 55° angled straight edge to mark the

angled tool head ways.

|

With the gib scraped, I turned my attention to the angled way of

the swivel block. I alternated printing the way between using a

straight edge and test fitting the tool head. Since I don't have a

60° angled

straight edge or template, I made do by using the tool head ways

as a template. I used both ways from the tool head to try and keep

the angle correct and used the straight edge to keep the surface

flat. It worked OK, but a proper template would have made it a bit

easier. Once I got some bearing points on the swivel block way, I

used it to mark the tool head. As you can see in the pictures

below, I was able to keep the scraped way pretty close to the

proper angle. One of the ways marked along the bottom edge and the

other shows color on top, bottom, and center. Now all I needed to

do was to scrape the tool head ways to get points along the whole

surface.

|

|

| Checking

for bearing on the tool head by marking from the swivel

block. There is some bearing, but not a lot. Excuse the

blurry picture. |

The

opposite side ways shows a little more color in the center

of the ways than the other side. It's about time to do

some more scraping. |

Before I could scrape the

angled ways of the tool head, I again needed to add some slots at

the vertex formed by the angled ways and non-bearing machined

flats above them. I have read of people cutting the slots with

bare hacksaw blades, angle grinders, and cutting them on a mill.

However, cutting them with a sharp corner of a scraper blade does

the job. The finish of the slot isn't that great, but it doesn't

need to be. The slot just needs to provide a place for the scraper

to run off so I can scrape far enough into the vertex of the

angled ways.

The angled ways are not very wide, so I chose to scrape the

dovetails with a hand scraper. It is much easier to control a hand

scraper than the Biax in such a small space. I also didn't need to

remove a lot of metal, so the scraping should go pretty quickly.

Since I could now use the scraped swivel block angled way as a

template to help me keep the angled ways at 60°, I wouldn't have

to use two worn angled ways and split the difference as I had when

scraping the swivel block. I will still need to take the tool head

back to the surface plate every few cycles to make sure that the

distance between the ways remains constant. Having the angled ways

parallel to each other is an important consideration.

|

|

| As with

the swivel block ways, there is no channel at the vertex

of the ways and non-bearing flat surface above the angled

way. |

Using

the edge of a 1/16" thick carbide scraper, I cut a channel

at each vertex.

|

After a bit more scraping

using both a 55° template and the 60° ways on the tool head as

printing masters, I began to get coinciding prints on the angled

swivel block way. I printed with the template first using the red

Canode, then print over the top of it with the tool head inked in

Prussian blue. I was looking to see if the two prints matched each

other. This would indicate that the angle of the swivel block way

matches the angle of the tool head way and that the swivel block

way is as flat as the print from my template can show. I've found

that when printing with the Canode first, the red doesn't smear as

much as if I print red on top of blue. The fact that I am using a

55° template on a 60° angled way doesn't affect the prints. All I

need is for the angle of the template/straight edge to be less

than the 60° angle of the ways. I am using the 55° template

because it is thinner than my 45° straight edge and doesn't

overhang the angled way as far. I would prefer to use an even

thinner straight edge if I had one. The wider the surface is on

the printing master, the harder it is to keep it perfectly flat

on the thin surface that I am trying to mark.

|

|

| This

print was made with the angled straight edge. I will make

another print with the swivel block to check for the

proper angle. |

The

second print from the tool head ways shows that I have

matched the angle of the ways pretty closely.

|

Once I had both the two

prints matching each other pretty well and decent points per inch

showing on the swivel block ways, I installed the gib and measured

the gibbed way and scraped dovetail using the 1/2" shafts again.

The divergence between being parallel was now down to within a

tenth of so. It only took a couple hours a night for a week to get

this far on one way. I'd never make any money at being a machine

reconditioner, but it's a hobby, so making money is not the

object.

The next step was to measure the remaining tool head way that fits

with the tapered gib. I again set up the two 1/2" shafts and

extended the pins on my surface gauge to measure the divergence

from parallel. I had one tool head way that had been scraped and

one that had not. As I had expected, the outer ends of the angled

way were further away than the center. I would need to scrape the

center section of the way until it was the same distance from the

opposite way as the ends were. To double check my findings, I

installed the gib on the swivel block and slid the tool head on to

the ways. I then tightened the gib and slid the tool head to mark

the ways. I had color only in the center, but was impressed to see

that the center portion was marked over the entire width of the

way. It won't take as much scraping to get this way good bearing.

With all of the scraping I have done, the gib now doesn't have

much adjustment left. I had figured that this would happen. I've

gone from a gib that wasn't seating deep enough to a gib that was

seating too deep. Considering how much metal I have removed from

the flat and angled ways, this was no surprise. The more I scraped

off the flat ways, the larger the space became between the angled

ways. To compound the issue, I have also had to scrape the angled

ways and the gib. My plan at this point is to finish scraping the

one remaining angled way and see if I have enough gib adjustment

to get the tool head to fit with a small amount of clearance on to

the swivel block. If not, I will shim the gib with some long

feeler gauge stock to get the proper clearance. Once I determine

the proper thickness of the gib, I will machine and scrape in a

new one. I've done this on my import miller with good results. I

do find it somewhat amusing that I started with a gib that was not

seating deep enough into the dovetails and now have to build it up

to get it to seat properly.

|

|

| Measuring

between shafts to make sure that the ways are equidistant

from each other. |

The

side of the tool head that the gib rides against is

starting to show some even color.

|

I finished up

scraping the last angled way on the tool head. Printing the gibbed

side angled way was more time consuming than the opposite side as

I needed to print from my straight edge in red, then assemble the

swivel block with the gib inked in blue to make another print on

top of the red. Once I got the spots to coincide on the two

prints, I could then start refining the surface for better

bearing. The picture below left was when I had finally got the two

prints to pretty much match up. After another few passes, I had

enough bearing points. By this time, I had no adjustment remaining

on the gib and was using a five thousandths thick feeler on the

back side of the gib to get enough thickness to lock up the gib.

I again measured the divergence between the two angled ways as

shown above. This time there was next to no movement on the DTI

dial. The tool head and swivel block were finally finished. On to

the next concern. I have been thinking about the lock not working

while I have been scraping. I posted a question about it on the

Yahoo Metal Shaper group and received some mixed views about

whether my last resort of tapping the tool head for a locking

screw would be a good idea. My first choice has always been to try

and get the lock working as it was designed before I attempt to

modify the tool head lock.

I think that my best chance of getting the lock working would be

to provide a new surface on the tip of the locking screw. Since

there is also a slight depression on the side of the tool head

where the screw contacts, I have also decided that I would like to

put a new surface on the side of the tool head. Since I found that

the machined sides of the tool head were parallel with the center

line of the angled ways, I will be able to come up with a fixture

to set up the tool head on my surface grinder and clean up the

sides of the tool head. I will also take a skim cut off the top of

the tool head to get rid of the battle scars around where the

clapper box attaches to the face of the tool head.

|

|

| Printing

with the swivel block and gib shows that the angle is

correct. I am almost finished scraping the tool head and

swivel block. |

Always

something. The coolant pump sprung a leak. I stripped

down the pump to find that the roto flex seal had self

destructed.

|

I had not used

my surface grinder much in the past year and have neglected the

coolant. I set up a cast iron block to do some test grinds

before I started work on the tool head. About half way through

grinding a 4" x 6" block, the coolant pump sprang a leak. It has

always dripped a little from the impeller housing seal, but now

it was coming out in buckets. Always something to keep me on my

toes.

I stopped grinding and stripped down the pump. I thought that

the coolant I had chosen had rust

inhibitors, but from the look of the inside of the pump and the

bottom of the tank, apparently not enough of them. The pump

shaft seal was totally shot. My DoAll manual shows the part as

being a roto flex seal, part number 090-029307. DoAll's web page

shows the old part number as 90029307 with a new number of 2930.

Unfortunately they are out of stock. I gave DoAll a call and

found that their parts department uses another number, 002930,

and that they expected stock at the end of the month - a week

and a half away. I ordered the part, then cleaned up the pump

housing and tank.

I rigged up a old pump I had to supply coolant to the grinder

and got back to doing my test grind the next day. The part came

out nice and square, but has repeating patterns on the surface.

Not deep enough to measure with any tool I own, but not the kind

of surface finish I was proud of. The old belt that turns the

spindle has taken a set. Tuning the spindle by hand, I could

feel a good deal of resistance in one position. I ground a

couple more test pieces and switched wheels a few times. The

more I used the grinder, the better the surface became and the

less I felt the resistance from the belt set. The belt still

need to be changed, but the surface finish was now good enough

for me to continue with this project.

|

|

| Lots

of rust. I need to find a coolant that will withstand

extended periods of inactivity. |

Setting

up the tool head on the grinder with a angle block and

1-2-3 blocks to keep the ways 90° with the magnetic

chuck.

|

I set the

tool head on the mag chuck and ground the top surface, then

checked it on the surface plate. The top surface and bottom

ways were true within a tenth and a half. When I checked the

sides of the tool head, they were out of square with the ways

and top surface by about a thousandth. I set the tool head up

on an 5" angle block with a couple 1-2-3 blocks under it and

clamped the tool head to the angle block. I checked the flat

ways and now found them square with the surface plate. I

transferred my setup to the mag chuck and again checked it for

squareness. I ground the one side, then flipped the tool head

over and ground the other side. I now had a tool head that was

square with itself.

The next issue to address was the tool lock. As I had said,

the 1/2" bolt that holds the lock body to the tool head

resides in a circular pocket. My thinnest walled 1/2" socket

didn't fit into the hole. On a chance, I tried a 13mm socket

and it fit with a tiny bit of clearance. I cleaned up the

mounting surface of the lock body and loosely attached it to

the swivel block. I assembled the tool head and tightened up

the gib so that it was locked up, then used some shim stock to

keep the distance between the lock body and tool head even. I

used some light duty thread locker on the bolt's threads and

tightened it up.

|

|

| I

found I had a 13mm socket that had thinner walls

than my 1/2". It took 0.012" in shims to prevent the

lock body from rotating during tightening. |

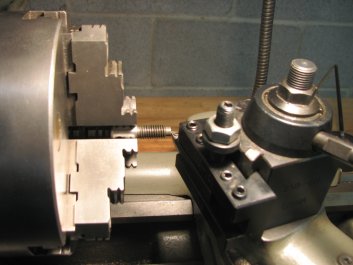

Test

fitting the lock screw after grinding the top and

both side surfaces. You can see the gib shim behind

the gib on the left side.

|

The last

step was to get rid of the slightly domed tip on the lock

screw. I removed the T handle from the screw and chucked the

screw up in the lathe and cut it square. I built a small jig

to hold the screw, then stoned the end of the screw to

improve the finish on its end. After reinstalling the screw,

it seems to be a lot better at locking the tool head.

I had cut a 0.007" thick shim to put behind the gib so that

I would have plenty of adjustment. While I will eventually

machine and scrape a new gib, I've decided to go ahead and

try the tool head out using the shimmed gib. I have used

some larger shim stock and was able to cut it to fit the gib

better than just using a feeler gauge. While I have made

gibs in the past that were not stress relieved, I would like

to stress relieve this one and that will require me to build

a heat treating oven. I've been thinking about building one

for a while and now have the reason and motivation to build

it. However, I want to finish the work on the shaper, so the

shimmed gib is going to stay that way for a while.

|

|

| I

turned the end of the screw square, then used a

fine stone to dress the end of the lock screw. |

The

tool head now seems to have much better gib

adjustment. The lock seems to fit better also.

|

I've also decided that I will paint the tool head before I

put it back on the shaper. While I hadn't planned on

repainting this machine, it seems a shame to spend all of

the time on scraping the tool head and leaving it with

peeling paint, so I now plan to paint the pieces I have

reconditioned. I like the darker gray that appears to be the

original color of this machine before it was painted over in

a lighter gray. Since I need to strip the old paint off the

tool head, it will take a week or so to complete. I will end

this installment by saying that I think that I have a pretty

good chance that the tool head will now lock and won't creep

down as it did before I reworked it. I am very pleased with

the feel of the tool head ways. It is a big improvement from

the way it was. The gib adjustment is now very smooth and I

am better able to regulate the tension supplied by the gib.

When I get the tool head back on the shaper, I will cut some

test blocks secured directly to the table, since the vise is

still in pieces. If I have stopped the creep, I will then

move on to scraping the table support and the boss it rides

on. Once that is complete, I will finally plane the vise

rails. I still have a fair amount of work to do, but I am

getting closer to completion.

©

Fager

September 28, 2015