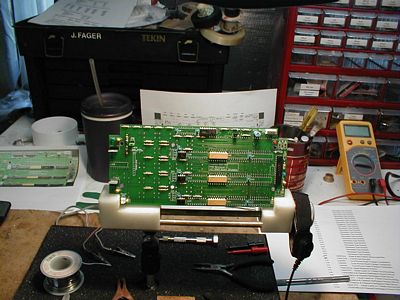

The circuit board is

partially assembled.

|

|

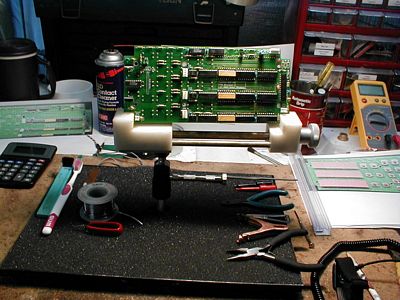

The

remainder of the ICs get installed.

|

|

The

tactile switches and displays are installed.

|

|

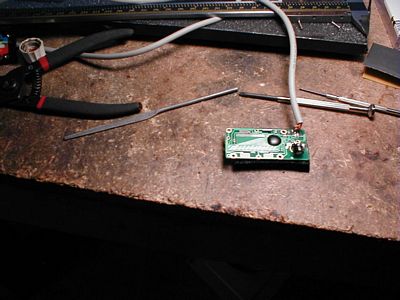

Soldering

a cable to a Harbor Freight digital caliper.

|

|

A

close-up of the same. A 100µF electrolytic capacitor is

substituted for the standard button type battery.

|

|

With

3-1/2 of the 4 caliper jaws removed, the caliper is transformed into a

digital scale and mounted.

|

|

Holes

are drilled free-hand in the saddle. It appears that before it

was beige, the saddle was painted red! Well, at least the other

side is beige.

|

|

The Y

axis scale is partially mounted.

|

|

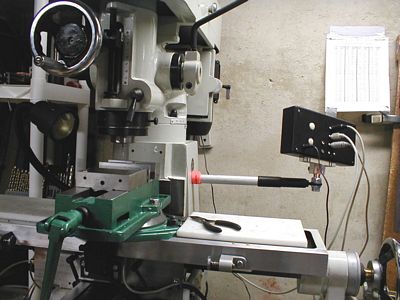

Control

arm and cover are installed.

|

|

Working

on the X axis. This is a temporary scale that will be used until

my new Jenix scale arrives.

|

|

The

caliper jaw is embedded into the plastic. Having this much

surface holding the jaw made for good support.

|

|

Bolt

holes are added.

|

|

Aligning

the holes for the cover. An extra drill bit holds the cover in

place while I measure for the next hole.

|

|

The

limit switch is remounted and the bumper is put in place. With

the temporary scale, my X axis was limited to just under 13 inches

until the new scale arrives.

|

|

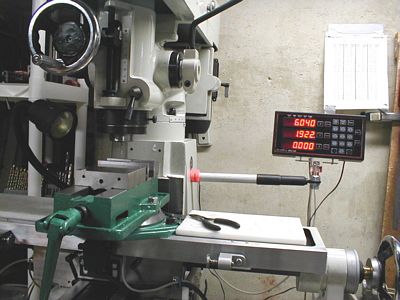

Testing

the read-out while still working on the bumper for the right side of

the X axis.

|

|

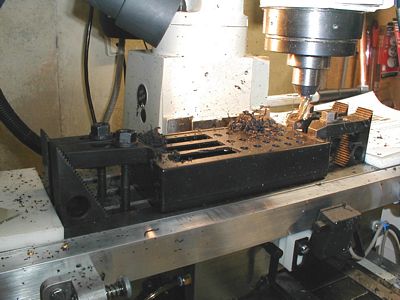

Using

the DRO for its first task. Cutting its own housing!

|

|

Wiring

the housing. The white circles are switches to switch between two

scales on the Z axis and to choose either RPM or electronic edge finder.

|

|

This

is the Fairchild photo transistor for measuring spindle speed, housed

inside a liquid and swarf proof HDPE box.

|

|

And

mounted. Looking up at the under-side of the spindle pulley

(which is a lot more shiny than it looks here).

|

|

An arm

holds the DRO in place and adjusts in length as well as allowing the

unit to swivel.

|

|

Scott

was out of over-lays (and I wasn't crazy about the blue lettering

anyway), so I made my own.

|

|

Done

for now. Step back and admire one very cool DRO.

My thanks to Scott for a useful and fun project!

|