Repairing a John Deere 317 - 48" Mower Deck

October 16, 2014

We've had a lot of rain

this summer and fall. (I wish we could ship some of it to

Southern California where it's needed.) Anyway, lately it seems

that every time I get ready to mow the lawn, it rains. This had

been going on for a couple weeks and the grass was getting

pretty tall. Finally mother nature strung together two sunny

days in a row and things had dried out enough that I could make

an attempt to mow. I did my routine checks of the little Deere

317 and found that the hydro sight tube was below its usual

level. Being in a hurry, I topped it off and fired the tractor

up. I thought it a bit strange that the hydro fluid was low but

there were only a couple drips on the ground under the tractor

and I remembered that I had spilled some Hy-Gard last year. I'd

check for leaks later. More rain was forecast for later this

afternoon and I had a few acres to mow. I backed the 317 outside

the garage and flipped the PTO switch so I could cut down the

weeds outside the garage door and started to mow. The mower deck

sounded good for a moment, then the pitch of the whirring blades

sounded different. "I know that sound," I thought. "Crap, I've

thrown the deck belt."

I swung around the

corner and drove straight into the shop. About 10 minutes later,

I had the deck belt covers off. It took me a couple moments to

make sense of what I saw. The center and left side spindle

pulleys were about an inch lower than the one on the right side.

I grabbed the center pulley and pulled. I was able to lift it up

about an inch. Something's not right here.

It turned out that the

sheet metal that supports these two spindles had cracked and

broken. The cracks appear to be from metal fatigue. I pulled the

deck off the tractor and removed all three spindles. The area of

sheet metal that supports the two spindles had failed pretty

spectacularly. The third one looked fine. With two spindles

broken free from their mounts, it was no wonder why the belt had

come off.

|

|

There's not a whole lot left of the mounts for

the center and left side spindle.

|

This is what is left of the center mount.

|

The mower deck on this tractor had seen some abuse prior to

becoming mine. After purchasing the tractor, I had had some

trouble getting the mower to cut level. When I stripped down the

deck and replaced the spindle bearings, I found that the deck was

twisted. Someone had run the deck into something pretty hard. I

had been planning to look for a deck shell or maybe purchase a new

deck this winter. However, I still have grass (and weeds) to mow,

so I was going to need to repair this deck for the time being. I

had some 16 gauge sheet metal left over from another project and

figured that I could make up some patch panels to repair the

damage.

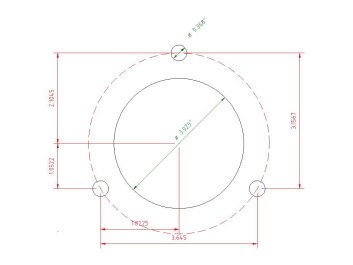

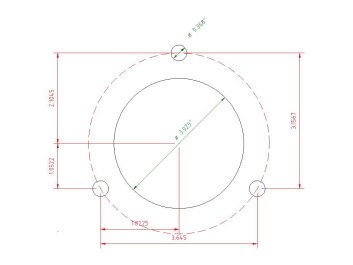

I took some measurements of the not broken right side spindle

mount and drew up a CAD sketch of the hole layout. The bolt holes

were a very close fit on the 3/8"-16 carriage bolts that hold the

spindles to the deck. I measured the holes on my deck to be

0.366". The closest drill bit I had to this was a letter drill

size "U" at 0.368". I measured the center hole at 3.025". I

figured that it had probably been an even three inches when new,

but there had been a lot of rust and corrosion since that time.

|

|

The left side mount is in pretty bad shape

too.

|

A CAD sketch of the mounting hole layout per

my measurements.

|

I made up a template using a piece of scrap clear plastic and

checked the fit. It was a very good match to the holes in the one

good mount I had left. After I got the patches installed, I

started thinking about the measurements I had taken. The

measurement I had come up with for the three mounting bolts was

2.1045" from the center point. This gave me a bolt circle of

4.209". I figured that on a new deck this bolt circle would

actually be 4.2". I ran my idea past an engineer friend and he

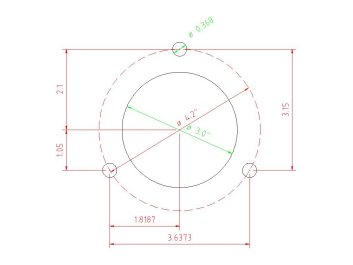

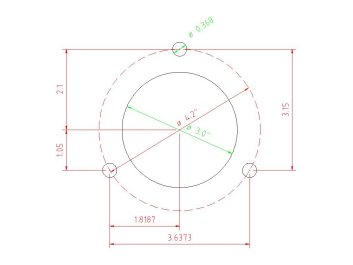

agreed. I drew up another CAD sketch with what I think are the

stock layout for the holes; a 4.2" bolt circle and a 3" center

hole. As I said, I used my first measurements and the patches came

out fitting real nice, but my guess of the proper measurements are

shown in the second sketch.

|

|

A revised sketch which is probably very

close to the mounting holes that Deere used on the

deck.

|

I made a Plexiglas template using the

original measurements I had made. It fit quite

well.

|

I made the first patch just large enough to cover the damaged

areas and give me some area to weld to. I cut a couple "V" shape

notches to make the patch easier to bend over the ledge at the

front side of the center mount. I used a grinder and orbital

sander to clean the metal under the patch as best as I could. I

liberally coated the cleaned metal under the patch and the back

side of the patch with flux and used bolts and clamps to position

the patch on the deck. I was hoping that the brazing rod would get

wicked between the patch and the deck and give it a little more

strength than I could get from brazing around the outline of the

patch alone.

Once I had one side of the patch secured, I heated a section of

the patch and formed it to match the deck with some auto body

hammers. I then brazed the newly bent section to secure it. I

continued this process as I worked my way around the patch. I had

considered securing the patch by cutting out the deck to match the

patch panel and using butt welds. It would probably have looked

nicer, but wouldn't have been as strong. I will have two layers of

metal for much of the mount. It also would have been more

work to match the raised area around the mount. Considering the

condition of the deck, my goal was to get it useable again. If I

can achieve that, I will be happy.

|

|

The template matched up with the spindle

housing as well. Time to cut some sheet metal.

|

The sheet metal has been cut and I am starting

to braze and hammer form it to fit the spindle

tower.

|

Once I got the first patch finished, I started thinking about the

second patch. This side of the deck had a lot of hair-line cracks

radiating out from the mounting area. The patch was going to need

to be a little larger. Again, the bolt hole area was missing for

one of the bolts and where the other two holes were, there wasn't

much metal that wasn't cracked. I decided to cut this patch in the

shape of a circle with a small flat area to fit down into the side with the ledge. To cut the circle, I

added the little table to my 4" X 8" horizontal band saw that

allows it to cut in the vertical position. I don't use this table

too often, but it sure came in handy for this project.

|

|

The opposite view of the previous picture. The

notches make it easier to bend the patch to fit the

spindle tower.

|

For the left patch, I started with a circle

with one flat side. The flat will get bent down to

align with the ledge to the front of the raised

spindle mount.

|

I made the circle seven inches in diameter

and set it up on a piece of pine board backing on my milling

machine. I marked the center of the disk and drilled the size

"U" bolt holes. I had looked up the size of a clearance hole for

a 3/8" bolt and found that size "W" is often used. Size "W" is

0.386". I had measured 0.366" on the rusty holes on the right

side of the deck. As my friend mentioned, it appears that the

design considerations were to minimize any play in the spindle

housing to deck junction if the bolts were to loosen. With the

size "U" bolt holes, the bolts are a very snug fit.

Next I turned my attention to cutting the 3.025" hole for the

center of the spindle housing. Since I don't have an offset

boring head, I made do with a fly cutter with an angled bit. The

fly cutter works well, but setting the bit to cut a precise hole

involves some trial and error. It took a few test cuts on some

scrap before I was able to cut the hole diameter I needed. Once

the bit was set correctly, cutting the center hole went quickly.

|

|

Drilling the letter size "U" (0.368") holes in

the patch.

|

Here I am using a fly cutter to cut the hole

for the spindle housing.

|

With the second patch made, it was back to brazing. I used the

same method as before and tacked one side, then heated and bent

the sheet metal to the proper shape. Again I used a lot of flux

between the patch and deck and fed brazing rod into the weld until

I saw that the bronze had been wicked between the parts. Once I

finished brazing the bottom side of the deck, I turned it over and

started on the top side. I clamped the broken fragments into their

respective positions and brazed them in place. Since the spindle

housings sit on the top side of the deck, my goal was to build up

the top side so that the two cracked mounts were at the same

height as the undamaged one. I have always had a belt alignment

problem with this deck due to the metal under the spindle housings

being bent and sagging a bit. Now I had a chance to improve the

alignment by making sure that the height of the deck was uniform.

There were lots of little pieces of broken sheet metal to clean

and braze into position. After I took the picture below of the

deck top side, I spent another couple of hours brazing, grinding,

and leveling the two mounting areas.

|

|

Both patch panels have been brazed in place.

|

On the top side of the deck, I brazed in all

the broken pieces. I did this so that the height of

the spindle housing would be the same as the not

broken right side.

|

When I finished brazing, both sides of the mounting areas were

ground and sanded flat and painted with a couple coats of primer.

If my repairs hold up, I will strip the deck down this winter and

get a few more coats of paint on it to try and keep the rust at

bay until I can find a nice deck shell to replace this one. A

wider deck would be ideal but they're even less common than the 46

and 48 inch decks, but who knows, I may get lucky.

When I was talking to my friend about the size of the bolt circle,

he mentioned measuring the spindle housing as another reference in

addition to measuring the holes in the deck. I have two different

styles of housings. One with slots instead of bolt holes and one

with square holes to capture the carriage bolts that Deere uses to

hold the spindle housings to the deck. After measuring the housing

with the square holes, I am pretty confident that the bolt circle

is 4.2".

|

|

Primed and ready for the spindle installation.

|

Comparing the two different styles of spindle

housings.

|

The last time I had the spindle housings out of the deck was

November 2010 when I replaced the spindle bearings and added power steering

to the 317. Four years later, all nine of the spindle housing nuts

and bolts came apart easily. The main reason for this was that I

used an anti-seize compound on all of the threads. I had never

used anti-seize on anything but spark plugs in aluminum cylinder

heads until we moved from California to Virginia in 1986. The

mechanics in the Maryland dealership I worked for used it for all

nuts and bolts that were exposed to weather and swore by it. With

road salt being used for winter snows and lots of rain the rest of

the year, there was a need for using it. In California we didn't

have much of a rust and corrosion problem. I started using it for

my projects at home and now wouldn't be without it. Last year, I

found a anti-seize product for use in marine environments. I

haven't been using it for long enough to know how it holds up

after a few years, but everything I have used it on has come apart

easily. I am hoping that it does an even better job than the

non-marine stuff I have been using for decades.

I lubed up all of the nuts and bolts and installed the spindle

housings. I sharpened the three blades and installed them. The

blades are getting pretty rounded on the ends. I think it's about

time to buy some new ones. I installed the belt and was real happy

that the idler pulley alignment with the center blade pulley was

better than it's ever been. This should make my belt last a little

longer. The deck was now ready to be installed back on the

tractor. However, there was one last thing to check.

|

|

The spindles are installed.

|

The blades have been sharpened and installed.

(I really could use some new blades.)

|

Last Tuesday when I thought I was going to mow, I had checked all

of the fluids before starting the tractor. While this is my usual

practice, finding the hydro fluid a little low in the sight tube

was not a usual occurrence. I topped of the level with Hy-Gard low

viscosity fluid and checked under the tractor for leaks. There

were a couple fresh drips on the ground and the bottom of the

transmission had some oily dirt on it, but it didn't appear to be

a big leak. I figured that I would pressure wash the tractor and

find the leak after I mowed. As it turns out, it is a good thing

that the mower deck had trouble and that I couldn't mow. The leak

only happened when the hydro was under power and it was a pretty

good sized leak.

I was pretty certain that I could silver solder the crack and

close it up, but the question was how long it would stay sealed.

The tube is attached to the bottom of the transmission and extends

upward to form a loop. When the tractor is running, the loop

vibrates and there is no upper mount to dampen the vibration. I

didn't think that my silver solder would hold forever, but I was

hoping that it would hold long enough to get the yard mowed before

our party on Sunday.

|

|

I found out where the Hy-Gard was going. A

hair-line crack 2/3 the way around the cooler pipe.

|

It was hard to see the crack in person. It was

harder to get it to show in a picture.

|

I started mowing around noon. It usually takes about four and a

half hours to get all of the lawns and the trails done. The deck

was working well aside from leaving a thin stripe of long grass

where the rounded ends of the blades didn't cut. I stopped every

15 minutes or so to check the cooler pipe for signs of leaks. No

leaks for almost two hours. I finished up on the back yard and

started mowing in front of the house. After a few minutes of

mowing, I decided to check the cooler tube again. This time there

was a drip hanging off the pipe. I'd better get the tractor back

to the shop. After I covered the 50 yards back to the shop, the

drip had turned into a tiny stream. I had caught the crack early

enough that I didn't lose more than a couple ounces of fluid.

|

|

Low

heat

from the Oxy-Acetylene torch, lots of flux and

some silver solder sealed up the crack, but will

it hold up?

|

I removed the adapter, cleaned the threads and

added some Teflon tape to help prevent future leaks.

|

I drained the Hy-Gard and pulled off the cooler pipe again. I

would order a new pipe on Saturday. I still wanted to get the lawn

mowed, so I decided to try brazing the pipe. I used a grinder and

a small disk sander to remove as much of the silver solder as I

could from around the crack. I coated the pipe in flux and heated

the pipe just enough for the brazing rod to flow and follow

gravity downward. With the crack facing down I added enough rod

that some drips started to form on the bottom of the pipe. I

was trying to get as thick of a coating over the crack as I could.

|

|

Using a 1-1/8" wrench to tighten up the

adapter.

|

A 1" wrench is used to tighten up the cooler

pipe fittings.

|

After the pipe had cooled a bit, I plugged one end and pressurized

the pipe using a rubber tipped air chuck. I dipped the pipe in

some water to look for bubbles. No bubbles were found, so

hopefully that means no leaks. I had been thinking that I wished

that there was some way I could secure the pipe so it didn't

vibrate quite so much. There may well be a way to secure the upper

looped end of the pipe, but that would mean pulling the fender pan

off the tractor to get a good look at the possibilities. That

would take some time and I didn't have a lot of time to spend on

the tractor right now. I decided that I could add a gusset

to the bend where the crack had formed and this might be enough to

buy me a few hours of mowing time.

|

|

Back

to the drawing board. This time I will braze

with a bronze alloy and hope for the best.

|

I let the braze drip a bit and made sure that

gravity guided the drips on top of the crack

|

I cut a small triangular piece of sheet metal and ground it to the

approximate shape of the bend. I covered the side that would be

facing the pipe with flux and tinned that side with braze. I did

the same to the area of the pipe that the gusset would attach to.

With low heat, I then brazed the gusset to the pipe. I

reattached the cooler pipe to the transmission and ran the Hy-Gard

that I had drained through some paper filters to make sure that I

hadn't picked up any dirt. I had used the last of my jug of

fresh Hy-Gard when I had filled the transmission on my first

attempt to seal the leak. Now all I had was what I had drained

before removing the pipe for the second time. I wasn't going to

have enough to fill the trans to the proper level and I wasn't

going to mow being low on fluid. I would hit the Deere dealer

tomorrow and get another gallon of Hy-Gard low viscosity when I

ordered the new cooler pipe.

|

|

To

reduce the amount of movement at the point where

the tube cracked, I brazed in a gusset.

|

Once again, I installed the cooler tube. It's

a little too dark to try it tonight but I am hoping

to be able to finish mowing the lawn tomorrow.

|

Saturday morning we took a ride up to the Deere dealer. I bought a

new belt for the deck, some Hy-Gard, and ordered the cooler pipe.

The parts counter guy said that the pipe should be in on Wednesday

with their stock order. I had no desire to pay extra to get the

part sooner. If I couldn't get the yard finished today, I didn't

really care if I mowed on Monday or even next Friday.

It took about a half hour to install the new belt and fill the

hydro. Time to see if it works. Again, I stopped to check for

leaks often. I found none. I got the front yard finished and

started on the trails. I was a little hesitant about mowing the

trails. There are lots of pot holes, tree roots, and rocks to

contend with. I would also be a good distance from the shop

if I developed a leak. However, the grand kids enjoy walking down

to the creek and the weeds were getting pretty tall. I took a

chance and mowed the trails. Fortunately the pipe held and even

hitting the big ruts didn't cause the crack to open up again.

After I get the new pipe installed, I will keep this old one as a

spare. As long as I keep it around, the chances are that I will

never need it.

© Fager October 18, 2014